The tool moves in the direction pointed by the arrow in the preview pane.Īt first the tool moves in the pointed direction and then backwards. After it the standard Color window in which the user can select the required color will be opened. To change the element color the user needs to click the corresponding color square. Īdditional elements that will be displayed in the preview pane are selected by checking the corresponding element in the Color legend tab.

The G-code settings window includes the following tabs with settings: General, Milling machine, Laser (cutting) machine, Workpiece zero point, Tools, Color legend, Advanced, Dispencer (Skyglass), GRBL, Lathe machine. The list is completed with the data from the Tools tab of the G-code settings window. The drop-down list includes the tool and its parameters. To change the tool lead out direction tick the Reverse lead out checkbox. Changes of the tool lead out method are displayed in the preview pane. The user can select one of the following lead out methods: tangent, normal, arc. To change the tool lead in direction tick the Reverse lead in checkbox. Changes of the lead in method are displayed in the preview pane. The user can select one of the following lead in methods: tangent, normal, arc.

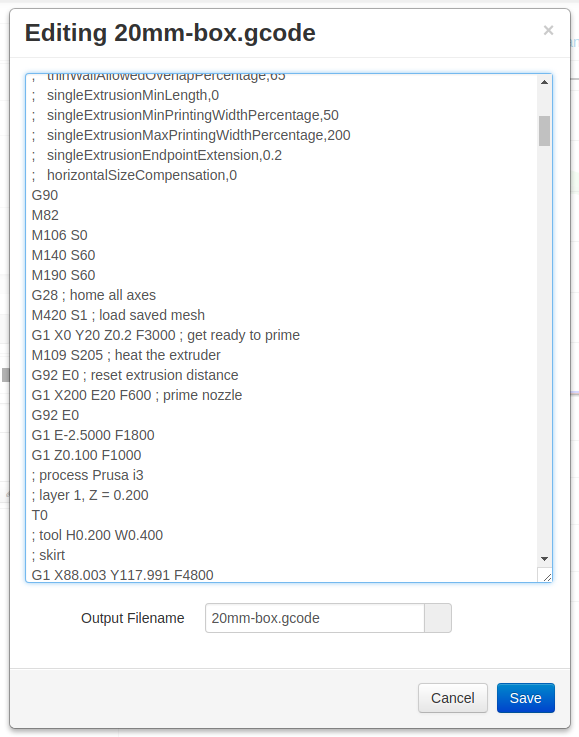

With the Outside option, the movement trajectory is located outside of the contour. With the Inside option, the movement trajectory is located inside of the contour. It is created using the tool radius with the help of the equidistance. The Rightward (G42) option compensates tool radius on the right of the trajectory.įor GRBL, the tool trajectory. The Leftward (G41) option compensates tool radius on the left of the trajectory. The Off (G40) option discards tool radius compensation. Includes a contour in the G-code precessing list.Ĭhanges tool direction from the start point along the selected contour. The file will be saved with the NC extension. In the opened window enter the output file name and click Save. G-code will be generated automatically.Ħ. To generate G-code for a laser machine select the required machine type in the G-code settings window on the General tab.ĥ. By default ABViewer generates a control program for a milling machine. If you do not need to convert any particular contours, open the Processing queue window and uncheck them.Ĥ. By default all drawing contours are converted. On the Output tab in the Conversion group select the CAD to G-code command.ģ. Open a DWG/DXF file and edit it if required.Ģ. To convert a file to G-code use the following instruction:ġ. The following entities can be converted to G-code: lines, polylines, circles, arcs, ellipses, splines, texts, multiline texts and hatch. G-code files are generated directly from DWG/DXF drawings. The program allows creating a control program (CP) in the G-code file format for CNC machines.

0 kommentar(er)

0 kommentar(er)